Item No :

C30-80 X70-300Order(MOQ) :

1Payment :

ttProduct Origin :

chinaColor :

BlueShipping Port :

shanghaiLead Time :

40dayWeight :

11TosBasic information

| Type | C30-80 X70-300 |

| Tile Type | Steel |

| Material width | 136-486MM |

| Effective width | 70-300MM |

| Warranty | 2 years |

| Key Selling Points | Long Service Life |

| MaterialThickness | Steel:1.0-3.0MM |

| Brand Name | FDS |

MACHINE FEATYRES

1.Cutting System

Material of the cutting:Cr12Mov with quenched treatment. It can decide cut panel dimension acoording to the

hydraulic drive and PLC computer control system easy quick change CZ size without changing mould.

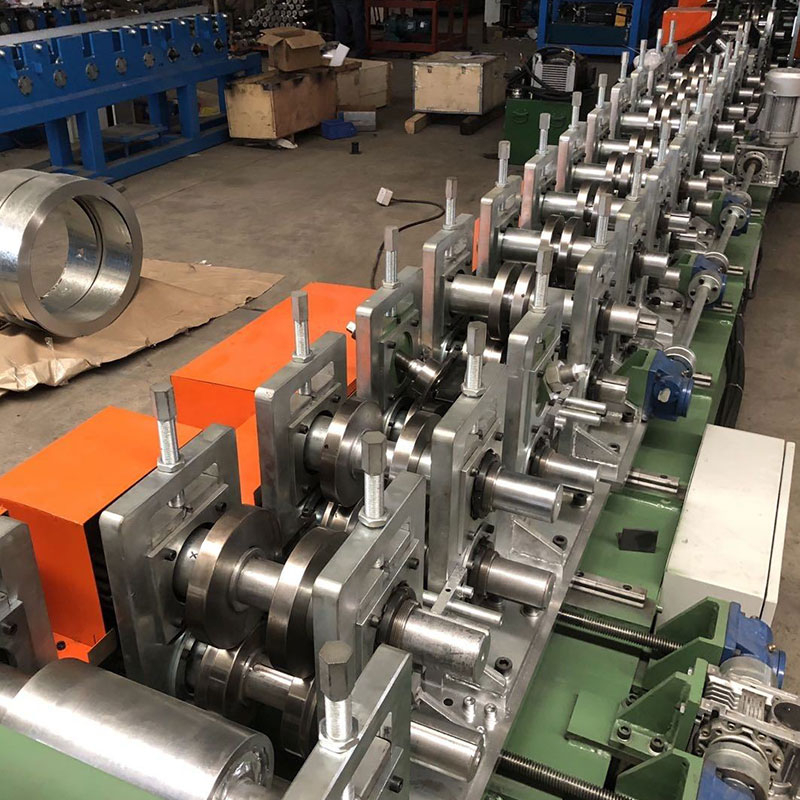

2.Roller System

Material of the roller:High grade Gcr15forged steel.Roller station: 18 rowsThickness of feeding material.

1.5-3.0mmThis wheel is designed to be more beautiful for every aspect of the product.

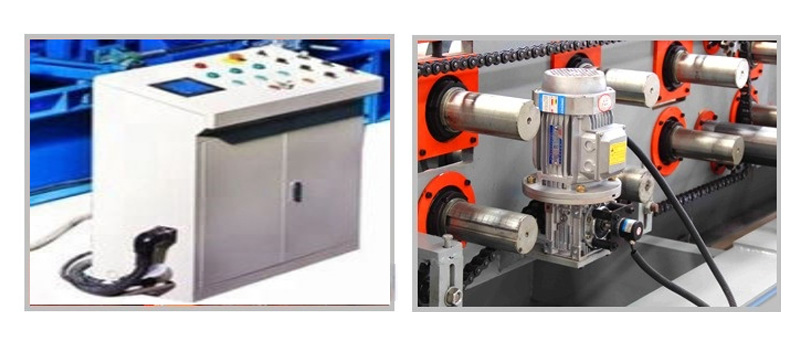

3.Computer Control Cabinet

Programmable setting of profile lengthand quantity,Computed mode has twomodes:automatic and

manual one.Language:English, Chinese,Spanishand Russian.

Through this motor to replace the differentmodels of product size range of 80-300mmSet the size you need,

it will changeautomaticly

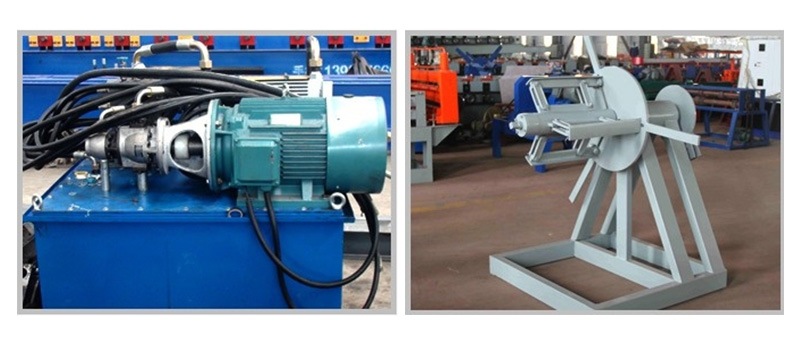

4.Hydraulic System

Power:22kw

Hydraulic oil: 46# hydraulic oil

Working pressure:12-16Mpa adjustable

Solenoid valve:3 qroups

Color:Blue (or as customer's request)

5.Manual Uncoiler

Loading capacity:5TInner diameter: 500-508mmSteel coil width:600mm

6.Receiving Table

Main framework adopts welded steeland supported roller,used for transmitand collect the

finished products.

Other detailes of C purlin roll forming machine

Suitable for material with thickness 1.5-3.5mm

Shafts manufactured from 45#,Main shaft diameter=φ95mm,precision machined

Motor driving,Gear chain transmission, 18 rollers to form and 7 rollers for straightening and levelling

Main motor=18.5KW , Frequency speed control. Forming speed approx.20m/min

PLC Control System (Touch screenbrand:German Schneider Electric/Taiwan WEINVIEW,

Inverter brand:Finland VOCAN/Taiwan DELTA/ALPHA,Encoder brand:Japan Koyo/OMRON)

Just adjust required WEB,HEIGHT and LIP by hand wheel with the help of

position clock(with digit display for easy operation) on it,

and then input the required production data on the touch screen.

It takes only 5-10 minutes to finish all. No need to change rollers or spacers or cutters

like traditional old style machine (which takes over 45 minutes for each production size changing).

Combined with: PLC, Inverter, TouchScreen, Encoder, etc

Cut-to-lengthtolerance≤±2 mm

Control Voltage 24V

User's manualin English

FAQ

A:- What is your payment term?

- 30% of the total payment should be paid as deposit ,the balanced should be paid after check the finished photos

and videos well ,we supply test report.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- 24 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free.

After the quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and

maintenance consulting in lifetime.Within quality guarantee period, except for failures caused by human error, repair parts

will be provided for free. After the quality guarantee period, only charge the production cost of the spare parts.Free technical

supporting and maintenance consulting in lifetime.

E:-Can you accept OEM?

- We can accept OEM

Related Products

curving machine flatttening cutting machine Floor Decking Folding machine Purline Machine Rolling shutter Roof Machine Standing Seam Roof Machine

Water guttar machine

Tags :